THE ALUMINIUM STORY BAUXITE TO ALUMINA: THE BAYER

In the production of aluminium from bauxite, the intermediate alumina (Al 2 O 3) is produced by a combination process; the alumina is subsequently smelted to aluminium

(PDF) Chemical Processing of Bauxite: Alumina and Silica Minerals ...

2022年1月23日 The Bayer process is a chemical process for refining aluminium hydroxide, Al(OH) 3 from bauxite; this aluminium hydroxide is subsequently calcined to produce

Mining and Refining – Process

Two to three tonnes of bauxite are required to produce one tonne of alumina. 90% of the global alumina supply of around 90 million tonnes is used in aluminium production. Alumina refineries tend to be located

Chemical Processing of Bauxite: Alumina and Silica

The Bayer process is a chemical process for refining aluminium hydroxide, Al (OH) 3 from bauxite; this aluminium hydroxide is subsequently calcined to produce alumina, Al 2 O 3.

Refining: Refining Process - The Aluminium Story

After the bauxite is mined, it is refined into alumina before it is ready to be reduced to primary aluminium. At the smelter, the alumina – now a powder – goes through the Hall–Héroult electrochemical process to convert it

Bauxite Mining and Alumina Refining - LWW

Bauxite mining and alumina refining are the upstream operations of primary aluminum production. This review article describes the industrial processes of bauxite mining and

Introduction: Primary Aluminum–Alumina–Bauxite SpringerLink

2022年1月23日 This book centers on the production of purified alumina (Al 2 O 3) that is used as a feedstock to smelting cells that convert alumina to purified aluminum (Al). The

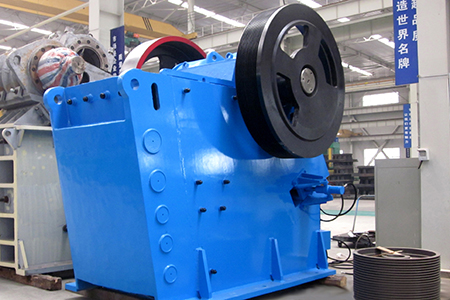

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022年1月23日 The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the

Alumina recovery from bauxite residue: A concise review

2023年11月1日 As the primary source of aluminum is bauxite ore, this has resulted in more accumulation of bauxite residue. A bauxite residue typically contains 15–25% of

The Transformation of Bauxite to Aluminum (and

Luckily, bauxite is in no shortage; experts estimate that the world has centuries worth of bauxite reserves available. Alumina. Alumina, or aluminum oxide (Al 2 O 3 – the material resulting from the Bayer

THE ALUMINIUM STORY BAUXITE TO ALUMINA: THE BAYER

Bauxite Ore Alumina Product Bauxite is the most widely distributed ore used for alumina production. It is named after the small town in southern France called Les Baux, where it was first mined. Bauxite is typically a mixture of hydroxides of aluminium with iron oxides, silica and aluminosilicates.

Aluminum processing - Ores, Refining, Alloying

Aluminum processing - Ores, Refining, Alloying: Aluminum is the third most abundant element on Earth’s surface. Only oxygen and silicon are more common. Earth’s crust to a depth of 16 km (10 miles) contains 8

Aluminum processing History, Mining, Refining, Facts

Ask the Chatbot a Question Ask the Chatbot a Question aluminum processing, preparation of the ore for use in various products.. Aluminum, or aluminium (Al), is a silvery white metal with a melting point of 660 °C (1,220 °F) and a density of 2.7 grams per cubic cm. The most abundant metallic element, it constitutes 8.1 percent of Earth’s crust. In nature it occurs

Bauxite Mining, Refining, Alumina Britannica

2024年8月28日 Bauxite, rock largely composed of a mixture of hydrous aluminum oxides. Bauxite is the principal ore of aluminum. Bauxites vary physically according to the origin and geologic history of their deposits: some deposits are soft, easily crushed, and structureless; some are hard, dense, and pisolitic,

Mining and Refining – Process

Bauxite discovered near Les Beaux in southern France by Pierre Berthier: 1847: Armand Dufrénoy names the ore “beauxite” 1861: Henri Sainte-Claire Deville renames it as “bauxite” 1854: Sainte-Claire Deville discovers a method to separate kilogram amounts of aluminium from its oxide, alumina: 1886

From Bauxite as a Critical Material to the Required Properties of

2023年10月25日 There is a long process to transform bauxite, a critical raw material, into a substance with the required properties of cast aluminum alloys for use in electro automotive parts. Thanks to its unique properties, aluminum has become the material of choice for clean technology manufacturers in applications such as use in the automotive

Tutorial:Setting up Aluminum Ingot production - Satisfactory Wiki

This page serves to guide you to set up basic Aluminum Ingot production, reusing all the waste Water. Aluminum Production is unlocked at Tier 7 - Bauxite Refinement. Once unlocked, you can set up Aluminum Ingot production. Aluminum Ingot production is done in 3 steps. The first step is producing Alumina Solution, which requires Bauxite and

Bauxite - EGA

The largest concentration of high quality bauxite is found in the north-west of the Republic of Guinea. Emirates Global Aluminium’s Guinea Alumina Corporation bauxite mine in the Republic of Guinea is a global supplier of bauxite. Our bauxite is relatively high in Gibbsite and low in Bohemite, reactive silica and organic impurities.

Bauxite Beneficiation: Efficient Way to Remove Silica in Bauxite

2023年2月15日 However, aluminum never occurs in the metallic form in nature, it exists in various aluminum-containing rocks. Bauxite ore, the primary aluminum ore, consists mostly of the aluminium minerals gibbsite (Al(OH)3), boehmite (γ-AlO(OH)) and diaspore (α-AlO(OH)), and is usually mixed with the two iron oxides goethite and hematite, the

Aluminum Smelting Furnaces and Processing of Bauxite Ore

The smelting of aluminum begins with the extraction of bauxite ore by a form of open cast mining. The bauxite is washed and screened before being converted to alumina, a white powdery element from which the aluminum is produced. Aluminum smelting is carried out in a Hall Heroult reduction cell, which is lined with carbon. A mix of alumina and cryolite

From Bauxite to Ingots: The Fascinating Journey of

2023年8月23日 From bauxite to alumina: the chemical transformation is a remarkable journey that brings forth a versatile material used in various industries. To begin, the refining process starts with bauxite, a mineral

Vedanta Aluminium patents innovative breakthrough in bauxite refining ...

2023年11月6日 This refining process generates bauxite residue as a by-product. To produce 1 kg of aluminium, it requires 2 kg of alumina, which consumes 6 kg of bauxite, leaving behind 4 kg of bauxite residue. Managing this voluminous by-product sustainably has been a long-standing industry challenge.

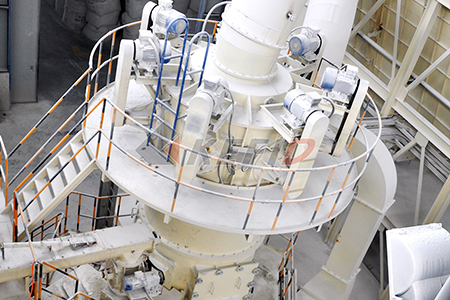

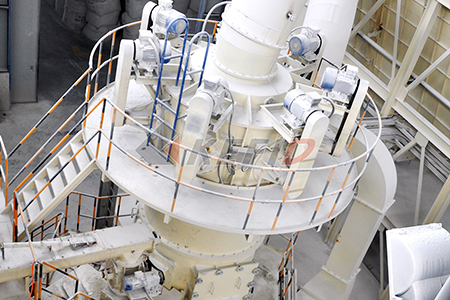

Alumina Refining - The Australian Aluminium Council

As water is a key input for refining bauxite into alumina, Australian alumina refineries are located in areas with reliable water supply. The Bayer refining process used by alumina refineries worldwide involves four steps: Step 1: Digestion .

A Review of the Extraction of Gallium from Bauxite Ores

2024年2月2日 Ion Exchange Method. The most widely used method for extracting gallium from Bayer's solution is ion exchange [].The ion exchange process includes adsorption, leaching of saturated resin and transformation of lean resin with dilute lye [].The seed mother liquid was first clarified by a storage tank, the temperature was lowered to 40 ℃, and the

Handbook Aluminum - From Bauxite mining to Alumina refining, Aluminum

Published epidemiological studies and quantitative exposure data for bauxite mining and alumina refining are virtually non-existent. Determination of possible exposure-response relationships for this part of the industry through improved exposure assessment methods should be the focus of future studies.

How to Extract Aluminum from Bauxite Ore? - Mining-pedia

2024年1月17日 The extraction of aluminum from ore involves a multi-step process encompassing mining, chemical transformations, and electrolytic reduction. From the mining of bauxite ore to the refining of alumina and the final production of metallic aluminum, each step plays a crucial role in obtaining this versatile metal.

Solved The refining of aluminum from bauxite ore (which Chegg

The refining of aluminum from bauxite ore (which contains 50% Al 20 3 by mass) proceeds by the overall reaction 2AI 20 3 + 3C -4A1 + 3C0 2. How much bauxite ore is required to give the 5.0 x 10 13 g of aluminum produced each year in the United States? (Assume 100% conversion) Ca. 1.3 x 1013 g 1.5.3 x 1013 C 1.9 x 1014 4.7.6 x 1014 e

How aluminum is made - material, manufacture, making, used,

Aluminum manufacture is accomplished in two phases: the Bayer process of refining the bauxite ore to obtain aluminum oxide, and the Hall-Heroult process of smelting the aluminum oxide to release pure aluminum. The Bayer process 1 First, the bauxite ore is mechanically crushed.

The aluminium industry: A review on state-of-the-art technologies ...

2020年2月1日 A typical bauxite refining plant is shown in Fig. 3. An overview of a typical refining process is provided in Fig. 4 with all discrete steps. Download ... it is cooled and released. The machine is able to reject quality-failed ingots by size, rotate the ingot to aid stacking geometry and stack them in the desired bundle ...